The 5-Second Trick For gearbox cvt

The 5-Second Trick For gearbox cvt

Blog Article

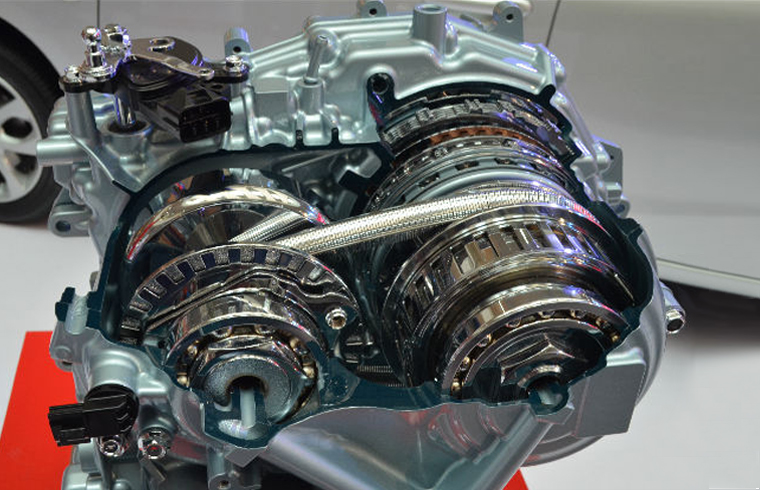

See where by this goes? The cones change the enter to output ratio over the fly, as dictated by computerized throttle input. This sets the “equipment” ratio (and engine rpm) according to whether the driver wishes successful cruising or acceleration electric power.

A CVT is much more efficient than a standard computerized, so that they do the job notably well in hybrid automobiles.

Despite the fact that this type of program looks dramatically distinct, each of the components are analogous to a belt-and-pulley system and produce a similar success -- a repeatedly variable transmission. Here is how it works:

You puuuulllll pull the toy backwards and the engine tightens…..so you pull it back…keep it…and “Enable it Go!”

CVTs may perhaps use hydraulic stress, centrifugal power or spring stress to generate the pressure needed to change the pulley halves.

The design principle dates back again to before the 1930s, with the original structure intended to convert rotary movement to oscillating motion and back to rotary movement working with roller clutches.[seventeen] This design and style remains in output as of 2017, to be used with lower-speed electric powered motors.

On the other hand, guide transmissions can nonetheless be more economical in precise situations, particularly when driven by a seasoned driver who can optimize equipment variations for gas personal savings. Total, CVTs have a tendency to offer better gasoline performance in metropolis driving and stop-and-go targeted visitors, While manuals may excel in freeway driving.

Identifying and addressing these problems early can reduce additional significant problems and increase the lifetime of the transmission. Typical maintenance and prompt awareness to any signs of trouble are important for making certain the longevity and reliability of the CVT.

The CVT company website gearbox was initially patented in 1886 While using the arrival of your motorcar. The CVT turned extra mainstream owing to DAF’s ‘Variomatic’ gearbox during the fifties.

Larger pounds. Because of the large oil strain at which a hydrostatic CVT operates, the pump and motor(s) are underneath sizeable mechanical stress, especially when highest electricity and loading is staying used.

It is very beneficial in mountainous locations. Just remember that these transmissions can have a hefty price tag on both of those the First buy and maintenance Expense.

A CVT also performs devoid of input from the driver, even so the similarities with a traditional automatic gearbox finish there. As an alternative to a number of gears, a CVT provides a set of pulleys – as a result it being known as a transmission, not a gearbox.

CVTs give a repeatedly variable gear ratio to keep the vehicle’s engine running inside its exceptional rpm assortment for any driving predicament. Occasionally often called a shiftless, stage-fewer, or solitary-velocity transmission, a single-gear CVT differs from a standard automatic transmission by offering various gear ratios. Even though Leonardo da Vinci intended the very first CVT in 1490 and Daimler and Benz patented their layout in 1886, the recognition of CVTs has snowballed in the last few years.

In lieu of making use of gears, CVTs utilize a belt or chain pulled tight involving two sets of cones on parallel shafts. A single can be an input shaft connected to the engine, one other is definitely an output that turns the wheels. You by now know how that works in a very geared transmission, so here’s the curveball.